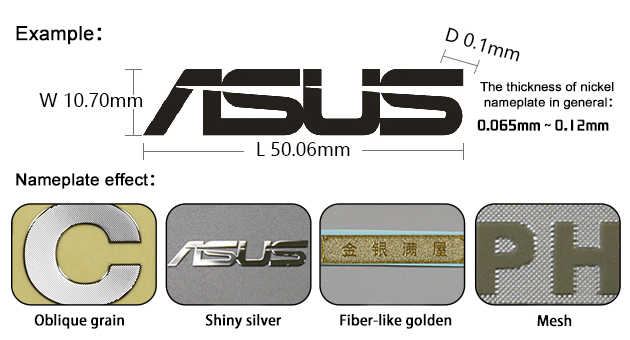

Material: Nickel

General thickness: 0.065mm, 0.08mm, 0.1mm , 0.12mm

Surface effect:

Available for bright (mirror), matte finish, silver, gloden, gun color, pearl nickel, net grain, brushing, Twill grain, cross grain, linen grain, fog surface.

Application of adhesive:

1. Water glue, brush glue on whole plate; Water adhesive is used for surface bonding. The bond strength is good,and it can be solidified under the condition of normal and medium temperature.And also features with the small solidified shrinkage rate, no yellowing, colorless and transparent, etc. It’s belong to environmental chemicals. It’s suggested to apply back adhesive for surface oil spraying.

2.Back adhesive for direct adhesion: The bonding strength of double-sided adhesive increases with the increasing of the area between adhesive and applied surface.Make stable pressure can help the contact between adhesive and the surface, thus increasing the bonding strength.To achieve the best bonding effect, the surface must be clean and dry.

3.Melt the hot glue through the hot press. Machine. Hot melt adhesive is easy to packaging, transportation, storage and no solvent, no pollution, no toxicity.The production process is simple, high added value, strong adhesion strength, fast speed and other advantages. It has a good effect even in bonding objects with uneven surface.

Properties of nickel label:

Precise copy without mould, Short time for sample production and development. Diversified surface effects, good anti-oxidation performance, bright metal colour and lustre; and easy to use.

Processes:

Receiving engineering drawings →polishing stainless steel plate →Electricity to remove oil →Brush insulating oil ink → roasting→ filming → Exposure & developing → nickel plating → chrome plating → taking out products → brush adhesive → changing films→ QC → clipping → packing

Technical principle:

The process of nickel think logo is made by cathodic deposition for forming process in the electrochemical process. Use electric mould as the cathode, use electroforming metal as anode,use metal salt of electroforming material is used as electroplating solution.The cathode is used as the cathode for electroforming metal, and the metal salt solution of electroforming material is used as electroplating solution.Under the effect of the DC current,the metal plate will gradually dissolve into metal ions that is in the anode, and it will be continuously replenished into the electroforming liquid which keep the concentration of the electroforming liquid in balance.And the metal ions lose electrons in the metal salt as are metal ions, gradually to the cathode movement and deposition on the master mould, through a period of time after a proper thickness (BoBiao most thin can be accurate to 0.04 mm).