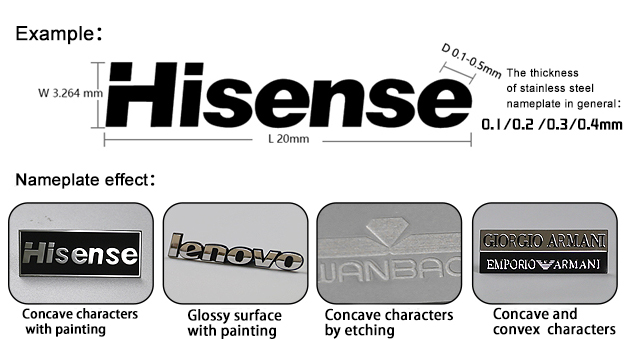

Concave character with painting, convex character with painting, etching, coloring

1. Water glue, brush glue on whole plate; Water adhesive is used for surface bonding. The bond strength is good,and it can be solidified under the condition of normal and medium temperature.And also features with the small solidified shrinkage rate, no yellowing, colorless and transparent, etc. It’s belong to environmental chemicals. It’s suggested to apply back adhesive for surface oil spraying.

2.Back adhesive for direct adhesion: The bonding strength of double-sided adhesive increases with the increasing of the area between adhesive and applied surface.Make stable pressure can help the contact between adhesive and the surface, thus increasing the bonding strength.To achieve the best bonding effect, the surface must be clean and dry.

3.Cotton adhesive, because the thick label have radian and concave, the common water glue and hot melt glue does not work, it can not completely attach on the product and need to use two layers of cotton adhesive; (it’s for thick label application).

Well corrosion resistance and good oxidation resistance. It’s weather-proof and well solvent resistance performance.The stereoscopic sense is strong. Retain metal color, clear edge contour, concave-convex texture, bright color, and the outline is sharp.

Receiving engineering drawings → preparing film → plate processing → photo-reception→ exposure → developing → roasting → etching → peeling off film → taking out products → printing adhesive → turning products over → cutting the plate → QC → clipping → packing

Stainless steel label: The stainless steel label is made by 304 stainless steel, which has good corrosion resistance to the atmosphere and fresh water medium, and the decoration effect is very high and beautiful through etching, polishing and drawing.The main raw material used in chemical etching process is ferric chloride.The below is the formula for ferric chloride corrodes stainless steel: ferric chloride, active agent, water. The formula of ferric chloride should be keep at about 42, and add activity 0.8 ~ 1.2m for each liter of ferric chloride in the formula.According to this formula, the stainless steel bottom surface is smooth and smooth which without black passive film and pitting.